Today’s task is to machine a bullet of aluminum into a lens cover for the lens testing equipment.

Lathe to turn down t the lender basic shape and then a dividing head will be used to machine the tabs which are used to security in place.

Hello is a picture of a lens mounting a piece used to fit a standard camera lens to a lens test equipment. He you can clearly see before tabs which i use to lock the mount in place.

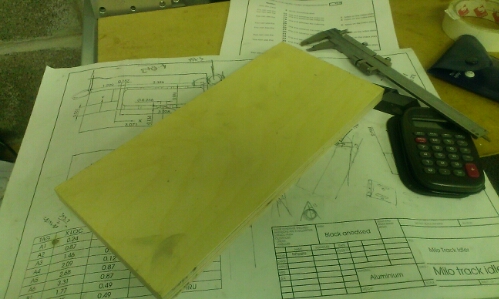

The restaurant has been drawn up to show the part i need to make. Parties to the machine from 3.5 inch tablet approximately 2 inches wide . This will feature the tab fixing brackets and a half inch diameter knurled handle.

First lady of malaysia news russian ballet . First lathe operations are within tolerance of -0.001+0 inch.

The next operation sis to mount the part 12 the dividing head on a mail and using a 3/16th cutter, mill the 4 tabs.

Clocking the milling machines we make everything central. we can fit a cutter and start making the tabs. The tabs need to reduce radius by 0.13 inch.

Final tabs milled. All I need to do is sand down the edges using 1200 grit paper and to test fit. I also need to do the knurling on the handle.

A quick sanding of the edges to remove the burrs gives us a time to test fit into the machine.

Rats, it doesnt fit there is a small pip which is used to locate the mounts into place. I think i need to add these in, but as it can be fitted in 4 orientations, i need to add 4 holes!

Back to the dividing head, this time, i need to rotate the handle 10 times – 10 into 40 go 4 times, and as we need 4, i can place it.

Carefully aligning it up so that the pip hole is in the centre of the tabs, and a slot is milled at the correct distance, we can mill using a 3/16 cutter.

Now to test fit!

Perfect! and it even fits in place once the cap is screwed!

JOB DONE!